PCB electroplating production line series products mainly include wet process equipment for circuit board, such as rubber slag removal and chemical copper precipitation, full board electroplating, graphic electroplating, electric copper nickel gold, chemical nickel gold precipitation, black oxidation, gold finger electroplating, etc; At the same time, we can design and manufacture different styles according to various needs of customers, including mini type, single arm type, gantry type, open type, coaming type, hanging type, floor type, manual type, semi-automatic, full-automatic, etc.

With the rapid development of electronic information technology, the manufacturing requirements for circuit boards are becoming higher and higher, especially the production of filled and blind hole circuit boards has been quite common. In order to meet this market demand, the company has developed a conventional vertical electroplating line for filled and blind hole circuit manufacturing.

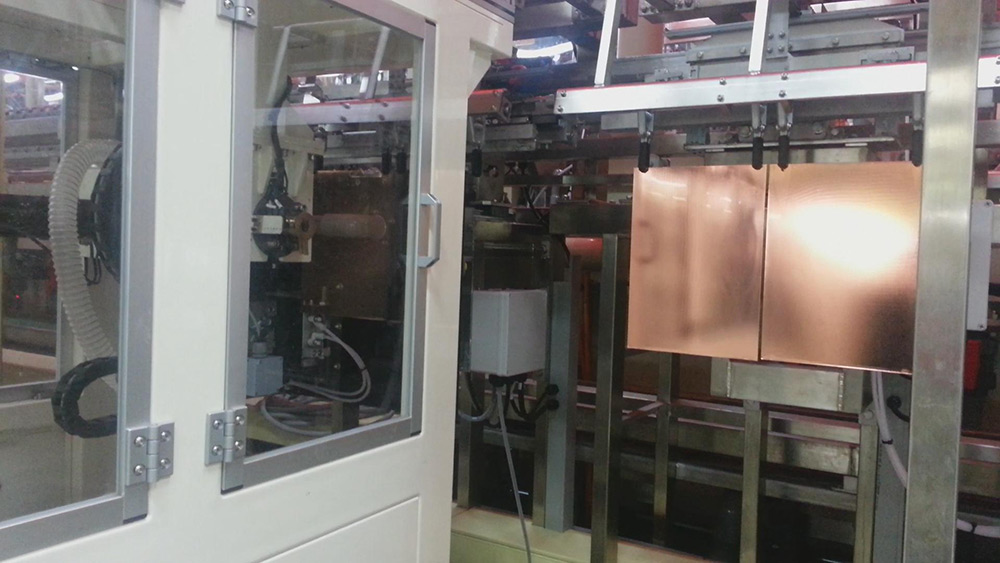

The full-automatic vertical continuous electroplating line comprises a pre-treatment part, a post-treatment part and a copper plating tank, the copper plating tank is located in the middle of the production line, and the pre-treatment part has two sets, which are arranged on both sides of one side of the copper plating tank; The post-treatment part also has two sets, which are arranged on both sides of the other side of the copper plating tank. This electroplating line can effectively improve the production capacity and occupy a small area.

Features: the vertical continuous electroplating line has good electroplating distribution, hole filling and hole filling ability, and the electroplating quality is stable. At the same time, the equipment also has the advantages of less waste gas emission, simple operation and maintenance, less occupied space, fully conforms to the design concept of environmental protection and energy-saving modern PCB equipment, and is suitable for full board electroplating, graphic electroplating, electric copper nickel gold and PCB process equipment with high aspect ratio.